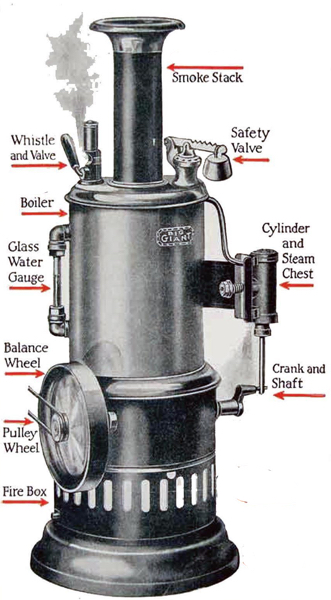

"Steam 101"

|

How a Toy Steam Engine

Works

Safety Valves You will find four basic styles of

safety valves, FIgure 1 is the most common, it has a

spring loaded plunger and threads into the boiler.

Figure 2 is an older style of the spring loaded

plunger, you unscrew the top to fill the boiler. Make

sure the plunger is free to move and there is spring

pressure with these two styles. Figures 3 and 4 are

weighted styles, the arm with the weight attached puts

pressure on a plug to block steam from escaping, lift

the arm up to fill boiler.

Burners If unit is flame heated fill burner

about half full with Wood alcohol, which is also known

as Methanol, Methyl Hydrate or Methylated Spirits.

Adjust wick height so tip of the flame just touches

bottom of boiler. Keep an eye on the water level in

the boiler, do not let it run dry. After a few runs

you will have a good idea how much alcohol to add to

the burner to get a maximum run time. Figure 5 is

common for most upright models, however larger units

may use double wick burners similar to figure 6.

Figure 7 is typical of most horizontal boiler models.

Alcohol vapors can communicate flame,

so fire doesn't have to touch the liquid, it can

ignite the vapor that comes from evaporating alcohol.

Always be sure the flame is extinguished before

refilling the burner, be aware that outside in

daylight it is often difficult to see the burning

flame.

With an electrically heated boiler it

is simply a matter of plugging it in and waiting for

the boiler to come up to pressure. With an

electrically heated boiler there is a greater risk of

boiling the boiler dry, it is very important to keep

an eye on the water level.

A note of caution, the

original electrical cords had two prongs with no

ground, for safer operation they can be changed to a

three prong configuration. Instructions here.

Boilers

|

Figure 7

Figure 7